Laser Welding

Laser Welding – Precise mechanical engineering with high intensity

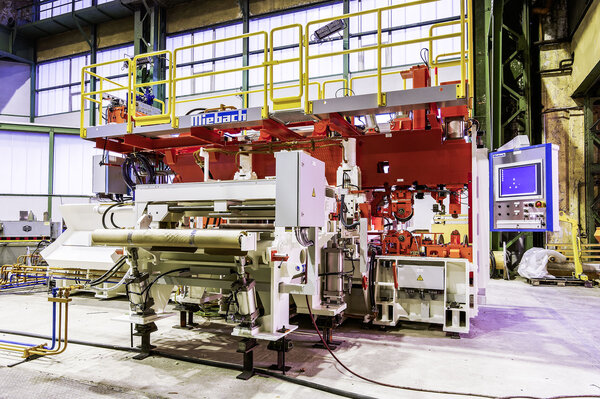

Miebach Laser Welding machines are the world standard for coil joining among international steel companies. Low cycle time, no over-thickness and minimal material structural change are the result of years of experience and continuous design improvements engineered into our laser welding machines.

Through the continuous development and innovation of our machines, we can guarantee our customers fast and reliable production through solutions that are individually tailored to their needs. We answer to the ever changing production requirements with a comprehensive customer focus. Our expert engineering capabilities provide the highest possible flexibility with regard to specific customer requests and the experience and expertise to sustain them.

Laser Welding

We have relied on the advantages of laser welding technology in our fully automatable strip joining machines, for many years. This technology extends the weldable quality range enormously and is distinguished from other fusion welding processes by high joining speeds with a very localized energy input. As a result, the heat-affected zone of the strip ends to be welded is kept low and the cycle time is significantly reduced. For the different tasks of our customers, we use CO2 and solid-state lasers in a customized range of machine types for sheet thickness ranges from 0.08 mm to 10 mm.

CO2-Laser

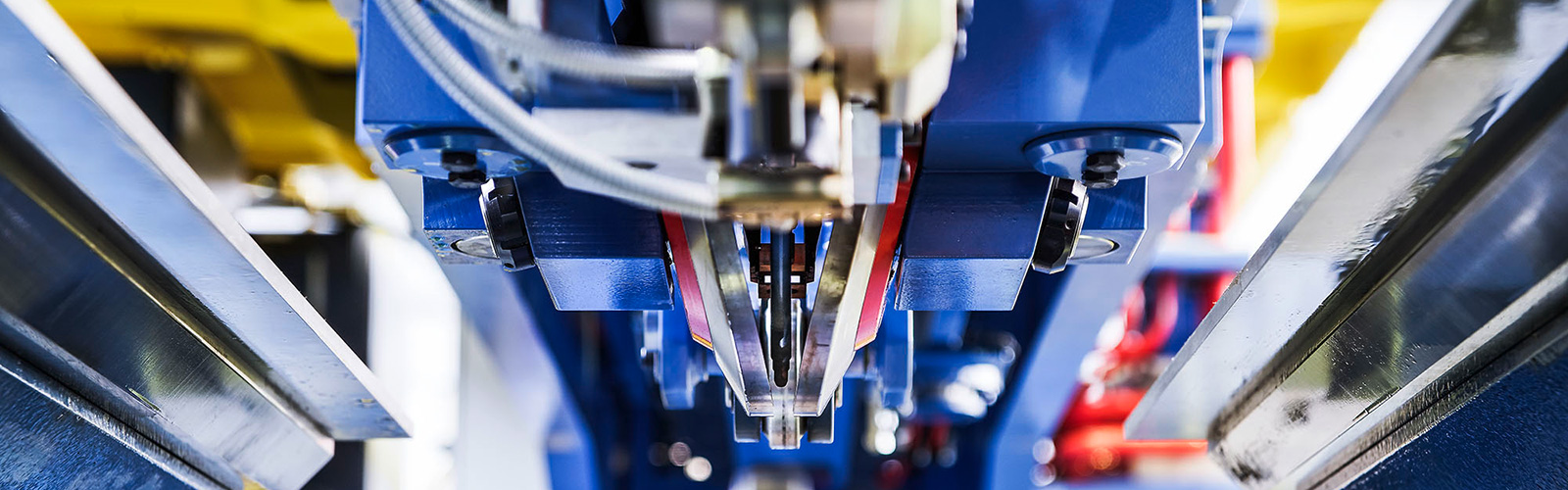

Over many years, we have adapted the process of CO2 laser welding exactly to the needs of our customers. Together with the manufacturers of the laser sources, the stability, ease of maintenance and adaptation to the ambient conditions in the steelworks were promoted. Thus, the specific properties of the CO2 laser enable a very quiet and robust process, resulting in seams free of spatters and no reinforcements.

Solid-State Laser

The maintenance costs by using the solid-state lasers could be reduced furthermore, compared to the CO2 laser and the beam guidance and alignment could be simplified. That is why solid-state lasers are increasingly being used in our machines. For this, we initially improved the stability of the process for larger strip thicknesses, so that these laser sources can also be safely used by our customers. Furthermore, besides the mechanical shears, we are already successfully using the laser as a cutting tool for preparing the abutting edges.

Hugo Miebach GmbH

Division Welding Machines

Dortmunder Feld 51

44147 Dortmund

Germany

Fon +49 (0)231 - 84 06 0

Fax +49 (0)231 - 84 06 123

info.ws(at)miebach.de

General Management

Dr. Andrey Fedoseev

Sales

Dipl. Ing. Michael Benning

Dipl. Kfm. Uwe Huhnd

Dipl. Ing. Sibylle Vedder

B. Eng. Henning Lamm

Dortmunder Feld 51

44147 Dortmund