Flash Butt Welding

Flash Butt Welding

Proven technology for complex geometry.

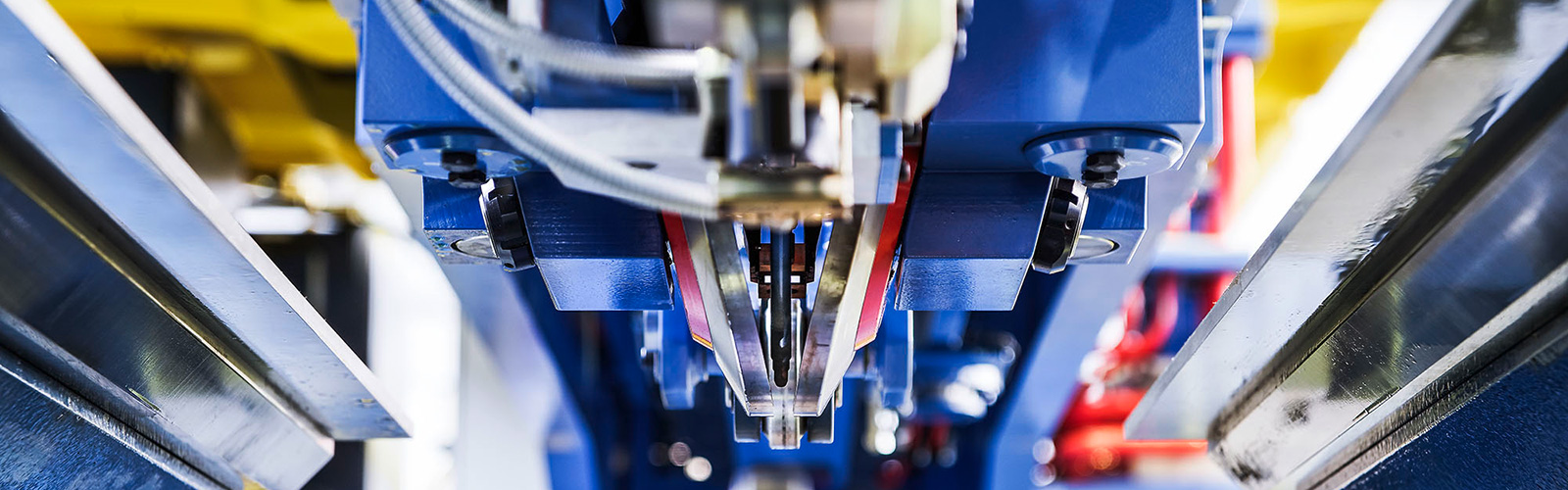

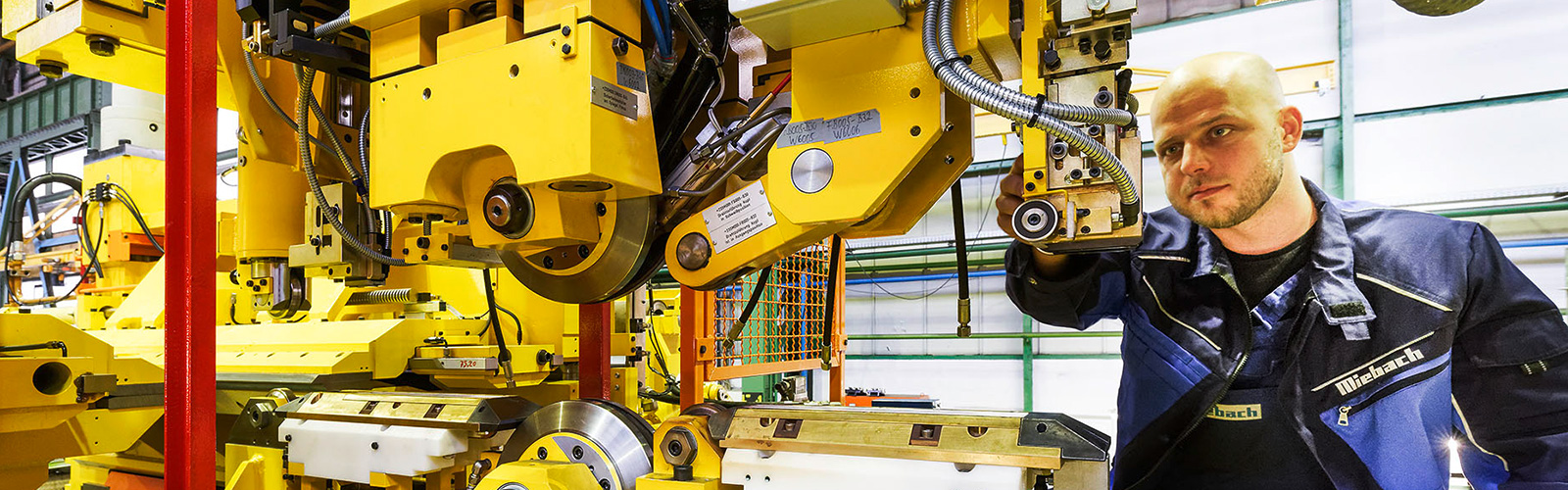

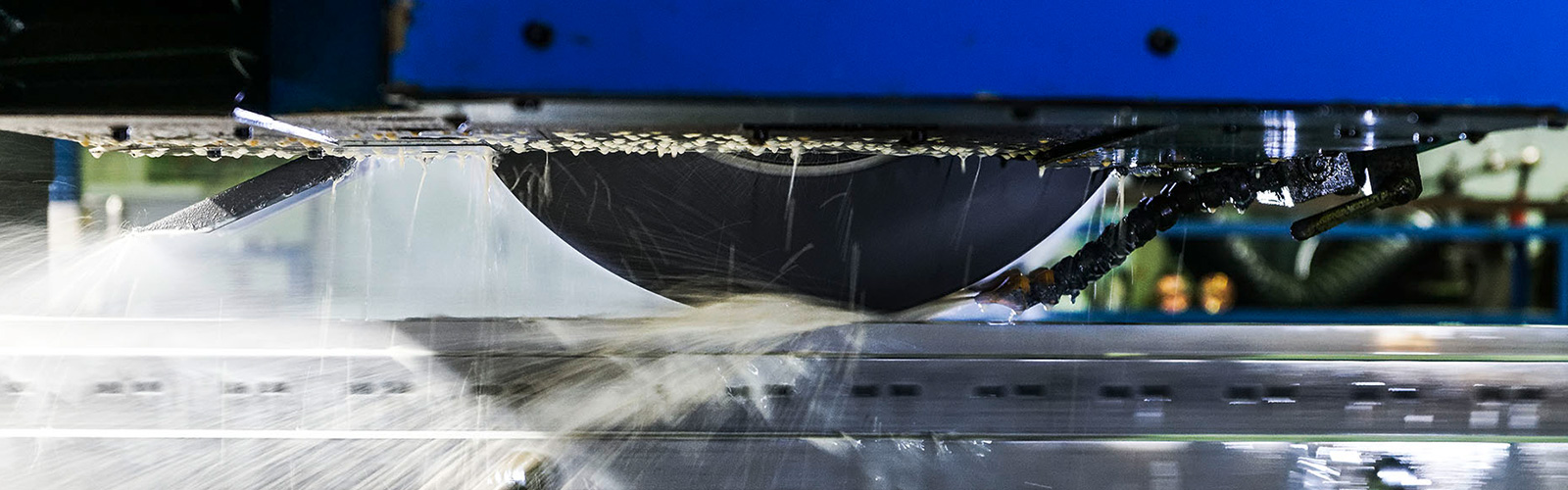

Flash Butt Welding is renowned for its high robustness in joining complex cross-sections in many different applications. The heating of the strip is regulated through the controlled flashing. Weld seam preparations are significantly reduced; contaminations and waviness of workpieces are negligible. Material is burned off during the flashing process resulting in a smooth, clean joint surface. After flashing, both surfaces are pushed together during the high speed upsetting operation where the strip ends are forged together. This eliminates discontinuities and ejects melted material out of the welding zone. The result is a high-quality joint with characteristics similar to the base material. With constantly improved machine designs, Miebach products bring the latest technology to this type of welding process.

Hugo Miebach GmbH

Division Welding Machines

Dortmunder Feld 51

44147 Dortmund

Germany

Fon +49 (0)231 - 84 06 0

Fax +49 (0)231 - 84 06 123

info.ws(at)miebach.de

General Managment

Dr. Andrey Fedoseev

Dortmunder Feld 51

44147 Dortmund

Fon +49 (0)231 - 84 06 131

info.ws@miebach.de